The Revolution of "Digital Craftsmanship" To Subvert Traditional Crafts

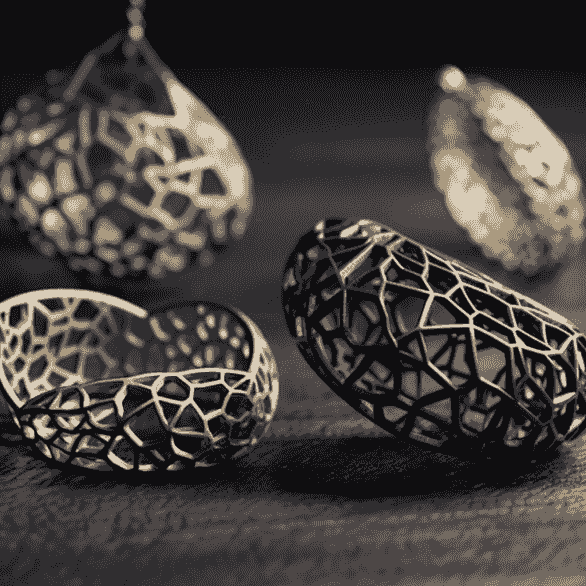

3D Printing and Elegant Electroplating

At Professor Sato Group, we are redefining jewelry making by combining cutting-edge 3D printing with precision plating technology, setting new standards in elegance, customization and sustainability. Using advanced DLP3D printing technology, we produce complex base designs with unparalleled detail and precision. Our plating process then adds the perfect metallic sheen, making each piece a striking, wearable piece of art.

Why Are The Top Jewelry Brands Using 3D Printing?

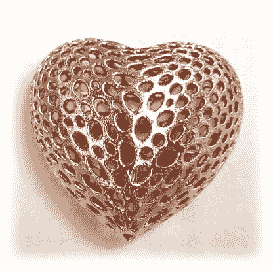

Ultra-precision printing

Restore the honeycomb microstructures that are difficult to achieve in Renaissance carving and metalwork, and achieve the "trap of light" effect - through precisely calculated hollow geometry, light is refracted inside the metal more than 7 times, creating a galactic vortex of visual depth.

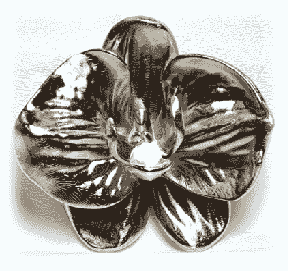

Biological mimicry engineering

A generative algorithm is used to simulate the growth logic of coral bones to create a "breathing" precious metal - 18K gold printed mesh structure that produces a 0.1mm elastic deformation when worn, as if it has a life rhythm.

Micromechanical joint

The 0.3mm diameter titanium alloy hinge system allows the butterfly wings of the brooch to open and close 2 million times at a frequency of 0.5 seconds per time without wear.

Magnetic suspension system

32 miniature neodymium magnets are built into the necklace to keep the central main stone permanently suspended in an anti-gravity state and move with the wearer to create a weightless ballet effect.

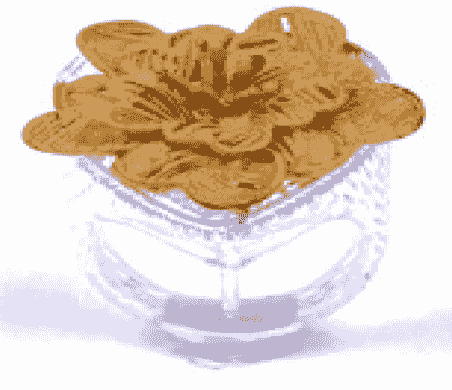

Advantages in Market Competition

1. Mismatched customization: Our technology enables designers and clients to explore complex, "bespoke" shapes that are not easily achieved with traditional jewelry making. This means unlimited design freedom, from delicate lace-like structures to bold geometric shapes, all with a luxurious metallic feel.

2. Sustainable and efficient production: By using 3D printing, we minimize material waste and reduce the environmental footprint compared to traditional metal processing processes. This is further enhanced by our electroplating technology, which uses only the necessary amount of metal to create durable, high-quality surfaces without overusing materials.

3. Light and comfortable: Our works achieve the look and feel of solid metal jewelry while maintaining the weight advantage of 3D printed structures. This approach makes the jewelry visually impressive while also being very comfortable to wear, perfect for today's demand for wearable luxury.

4. Affordable Luxury: By combining 3D printing with electroplating, we offer high-end, customizable jewelry at a fraction of the cost of traditional metal casting, offering a competitive price point without sacrificing quality or appeal.

Our 3D printed electroplated jewelry combines artistic vision with technical precision to meet market demands for personalization, sustainability and quality. It's not just jewelry, it's the future of personal expression.

This is not simply a technological replacement - it is a redefinition of luxury with quantum physics